You’ve probably had some trouble finding some of your favorite products online or on the shelves recently. Cars, medications, food, and lumber are just a few of the items that have been in short supply.

Supply chain disruptions have, unfortunately, become par for the course this year. In fact, they were up 638% in 2021 — a number that’s both shocking and frustrating for business owners in certain industries.

If you sell products that fall into any of the scarce product categories — or craft items that use any of those materials — you may be scrambling to figure out just how to handle things. Let’s take a look at a few ways you can handle supply chain shortages, maintain revenue, and keep your customers happy and informed.

1. Assess your own supply chain

↑ Back to topTake the time to analyze all the pieces of your manufacturing and fulfillment process. Understand where every item and material comes from, what each one costs, how long each one takes to arrive, and where there are any gaps or delays. Visibility is absolutely key to improving the process and overcoming any shortages.

Once you’ve done this, look for areas of improvement. Can you place larger purchase orders so you have more materials or products on hand? Can you pay a bit more for faster shipping to avoid lulls in delivery?

If you’re having issues getting items from one supplier, you may want to search for an alternative. While this won’t always help in cases of global shortages, it could be a good option for specific cases. If the issue is with overseas providers, for example, a local manufacturer may have more availability. And, though they could be a bit more expensive, it’s better than having no products to sell at all.

Diversification is a good strategy in many cases, anyway. If you work with several suppliers for the same items, you have a backup when something goes wrong.

2. Search for alternate materials

↑ Back to topThis is the perfect time to get creative. If you’re having trouble finding a specific material or if it’s gotten extremely expensive, think of alternatives you can use. For example, if you typically use lumber to craft your products, consider bamboo, hemp, or wood composites. If you’re having trouble finding rubber, you might try using silicone instead.

Or if shipping and packaging materials are in short supply, embrace your brand and be unique! If you sell knitting supplies, why not fill shipping boxes with yarn instead of bubble wrap? If you sell snacks, include a couple bags of popcorn that also act as lightweight padding.

3. Notify your customers of delays and shortages

↑ Back to topOne of the most important things you can do is keep customers abreast of shortages, items that are out of stock, and shipping delays. In most cases, people will understand if you let them know ahead of time. But if they find out after they’ve already placed an order, they might become frustrated. So how can you do this?

- Add a notice to your entire store. One of the best ways to display an important message is with a store notice that appears on every page of your site. Inform customers about production delays or item shortages so they know ahead of time.

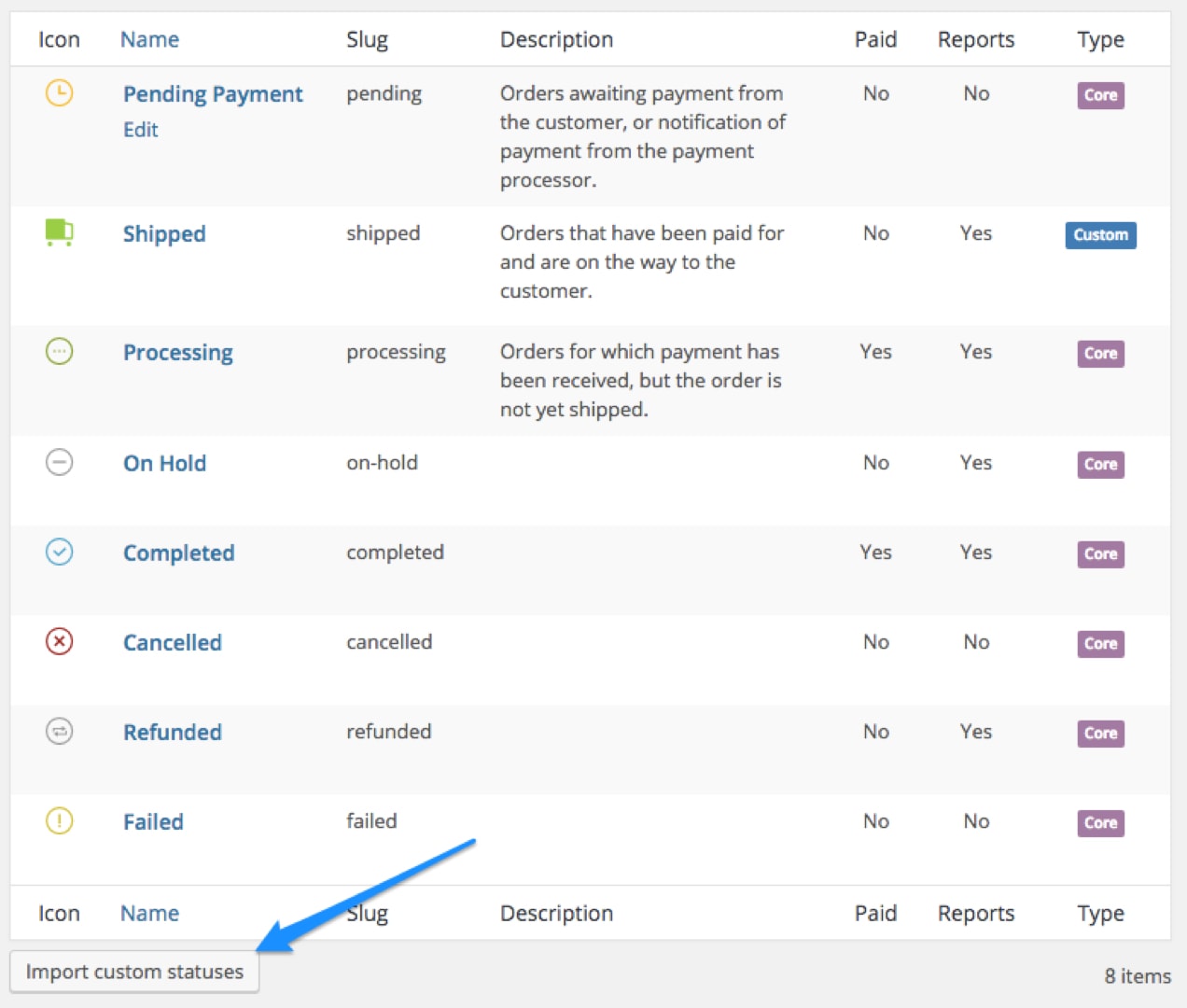

- Create new order statuses. Add new order statuses and send emails based on them so that customers know exactly where their item is in the fulfillment process. For example, you might create one for “item in production” or “order shipped.”

- Include information on the Cart page. Remind customers one last time that items might be delayed so they know what to expect.

- Make tracking information readily available. Let shoppers check on their order and know where it is in the delivery process.

4. Stay on top of your inventory management

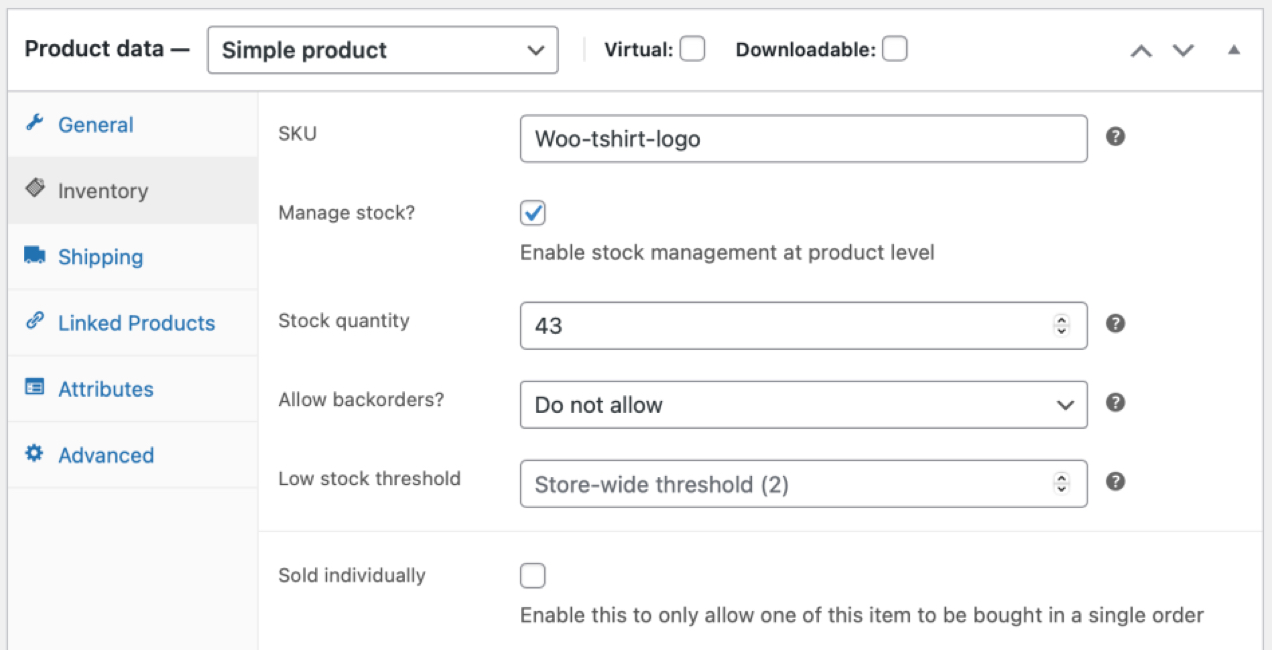

↑ Back to topInventory management is going to be absolutely critical here. The last thing you want is for people to purchase an item that’s out of stock and unavailable.

You may want to start by going through your warehouse or fulfillment center and getting a good understanding of exactly what’s in stock (and what’s not!). Then, update your online inventory accordingly. If you know that an item is becoming hard to find or difficult to manufacture, consider marking it as out of stock altogether for the time being.

Also think about using an inventory management tool — the easiest way to automate the process. This is especially helpful if you sell in additional locations like a retail store, local market, or online marketplace like Amazon. Everything’s synced perfectly so all the information is always up to date.

5. Add a waitlist option to your store

↑ Back to topA waitlist can be an excellent way to prevent missed sales opportunities even while items are out of stock. Loyal customers — and even excited new shoppers! — may be more than happy to wait until you get more products on hand.

With the WooCommerce Back In Stock Notifications and WooCommerce Waitlist extensions, shoppers can sign up for email alerts and receive a notification when a product is back in stock.

6. Adjust pricing as necessary

↑ Back to topYou may still be able to find the materials and products you need, but they could be a lot more expensive than they previously were. And that means you might need to increase prices to maintain profits. After all, the prices that consumers pay for goods jumped 5.4 percent just in September of 2021 due to higher manufacturing, labor, and material costs.

Sit down and analyze what you’re paying for products and materials so you can get a good idea of how to maintain profits. Once you’ve figured out the right number, you may want to let existing customers know what’s happening so they won’t be shocked the next time they visit your store.

Send an email or reach out personally to your most loyal shoppers, like wholesale customers. The more notice you can give them, the better. Let them know why you’re increasing prices, inform them about the new prices, and give them the opportunity to reach out with questions.

7. Reduce waste

↑ Back to topLook at your fulfillment process and figure out ways to reduce waste. The fewer materials and products that get thrown away, the more you can sell. Here are a few areas you can examine and improve:

- Packaging. How can you best protect your products during shipping to prevent breakage or spoilage? Consider including extra padding, investing in higher-quality boxes, and ensuring that refrigeration is top-notch.

- Storage. How are your items stored to prevent accidents, breaks, and spoilage? Are there ways that you can improve?

- Manufacturing. Are you making the most of every ounce of material? How can you reuse or repurpose items?

- Returns. Think about ways to minimize returns, like being upfront with product descriptions, including accurate photos, and answering as many questions as possible prior to purchase.

8. Have an emergency stock and work ahead

↑ Back to topStay ahead of any issues as much as possible. Don’t wait until you’re completely out of materials or items to place a new purchase order. Instead, order ahead of time.

You may also want to keep an emergency stock of manufacturing materials, packaging materials, and products on hand in case you do encounter a delay or shortage. This will enable you to keep things going as planned for as long as possible until you get the items you need or find an alternative solution.

Stay informed and in touch

↑ Back to topEven though supply chain shortages can be frustrating and scary at times, there are ways you can push through and keep your store running smoothly. It’s all about staying on top of your processes, understanding ways you can improve, and keeping in touch with customers as much as possible.

What solutions have you found to handle supply chain shortages? Let us know in the comments!

About