If you’re already running your online store, you know just how crucial efficient fulfillment is to a successful business. And if you haven’t started yet, you’ll soon find out.

When you have a solid fulfillment plan, all the logistics behind the scenes run smoothly and orders get delivered on time. A strong plan also protects your costs and minimizes liability.

The result is that your customers are happy because they get their products quickly and in good condition, and your bottom line is happy because your costs line up perfectly with your budget. Your ecommerce accounting team will be thrilled.

Whether you’ve just recently identified the best online business to start and are only beginning your journey, or are looking to refine the processes you already have in place, understanding the fundamentals of fulfillment is key. In this post, you’ll learn the basics, find out how to choose a fulfillment partner, and discover some incredibly-helpful fulfillment optimization tips along the way.

What is ecommerce fulfillment?

↑ Voltar Para o TopoFrom most people’s perspective, ecommerce fulfillment starts the moment your customer places an order and ends when the product hits their doorstep.

The reality, however, is that ecommerce fulfillment really starts the moment you initially source items to sell and store them in your warehouse, and it only ends once there’s no chance of a product going through the returns process.

Effectively managing ecommerce fulfillment matters a lot for business success. When products are delivered on time, you build trust and increase customer retention. You also reduce costs associated with processing returns.

What is the order fulfillment process?

↑ Voltar Para o TopoOrder fulfillment is an involved process with many steps. Between procuring products and delivering them to customers, there’s a lot to do and plenty of room for missteps.

Let’s take a detailed look at order fulfillment from the very first step, before customers even place an order — possibly before you even set up your online store.

1. Procurement and sourcing

Before you can sell any products, you need to find a supplier or make a manufacturing plan. This step involves identifying and negotiating with vendors who can provide high-quality products consistently. Even if your business makes its own product, you’ll still need a recurring source of raw goods.

The goal is to maintain an adequate supply of inventory without overstocking. It’s a delicate balancing act to always have enough to meet demand, but not so much that you have to spend unreasonable amounts of money storing unsold goods.

Strategic sourcing also helps in managing costs, ensuring product quality, and establishing a supply chain that can adapt to changing demand or disruptions.

2. Warehousing and inventory management

Once products are sourced, they need to be stored in a way that allows for efficient retrieval when you receive an order.

This may involve items being received at a distribution center, a type of warehouse where goods are stored and sent to the appropriate fulfillment centers when needed. From there it moves to a fulfillment center, like your business warehouse, where items will be picked, packed, and shipped.

Depending on the size of your business and the type of fulfillment you choose, this process may look very different. You may have a third party handle fulfillment at their warehouses, or products may simply come to your small business office (even your house!).

3. Order processing

Order processing starts when a customer places an order and ends when the product is ready for shipment.

Stock availability is checked, customer info is verified, and the payment is processed. All of this is done using automated systems. After that, the fulfillment center gets a notification and the next steps of the fulfillment process begin.

4. Picking and packing

Once an order is placed, items need to be found in the warehouse (picking) and prepared for shipping (packing).

For larger operations, automated software is used to help warehouse employees navigate and find the products they’re looking for, and the warehouse is organized so products are grouped in intelligent ways.

If you’re starting from home, you may have shelves dedicated to certain products or bins with various SKUs. But one way or another, you need to have products organized and easily accessible for quick processing once you receive an order.

This step must be handled with care to avoid errors, such as sending the wrong item or the wrong quantity, which can upset customers and cause excessive returns to clog up your supply chain and eat away profits.

5. Shipping and delivery

The final step in the fulfillment process is shipping the order to the customer. After the product is packed in the warehouse, it’s handed over to a carrier who brings the item to the customer.

This process includes selecting the right carriers, paying shipping costs, and providing customers with tracking information. Balancing fast shipping and cost-effectiveness is the key here. Customers are happy to get their items sooner, but it can result in unreasonable shipping costs.

If you’re just starting out, you can buy a small label printer and use WooCommerce Shipping to save on costs. From your WordPress dashboard you can purchase and print labels for quick, seamless processing.

Once the product is delivered, fulfillment is over — or is it?

Returns

Even if you have super efficient warehouses, flawless automation systems, and the fastest carriers in the world, something will still inevitably go wrong. Products may arrive damaged, people receive the wrong item, or maybe the customer just decides the product isn’t for them.

Sending a product back through the supply chain is known as reverse logistics, and it can be a burden on unprepared systems.

On the front end, this requires stellar communication from your support agents to understand the problem and set up the returns process. On the back end, you’ll need to receive the returned item, assess the condition, restock it if it’s still usable, and issue a refund or replacement.

There’s a tendency to get hung up here, as many supply chains aren’t designed for reverse logistics and can fail. Be proactive and ready for inevitable returns.

Ecommerce fulfillment service models

↑ Voltar Para o TopoDetermining the best ecommerce fulfillment strategy for your online store is one of the most important choices you’ll make. This determines how your products are stored, managed, and delivered to customers.

There’s no one best model here — it’s all about how you want to design your business. From managing all orders within your own facilities to outsourcing entirely, each of these has its advantages and challenges.

In-house fulfillment

Do you want to handle the entire logistics process yourself? Run your own warehouses and/or distribution centers, pack your own orders, and pick your own shipping carriers? In-house fulfillment involves managing the entire process using your own resources and facilities.

While you’ll need to use your own warehouse space and hire staff (or operate as a one-person show as you grow!), this model allows complete control over inventory, branding, and the customer experience.

Pros:

- You have total control over the fulfillment process.

- Store owners can maintain direct oversight of inventory, potentially leading to better inventory management.

- Merchants have the ability to customize packaging and inserts to enhance branding.

Cons:

- An investment in infrastructure, technology, and staffing is required.

- It can be resource-intensive, diverting focus from core business activities.

- Scaling operations is challenging and costly as order volumes increase.

Best suited for:

- Large businesses and enterprises with specific handling or branding needs that are not easily outsourced.

- Companies that maintain high margins and can absorb the costs of managing warehouses.

- Businesses with a stable order volume that does not fluctuate.

- Small businesses and solo-preneurs with no warehouses at all and minimal startup capital.

Third-party logistics (3PL)

When the size of your business rests somewhere between “tiny home-based shop” and “sprawling enterprise with dozens of warehouses”, third-party logistics (3PL) is what most businesses elect to go with.

A 3PL provider is a type of ecommerce fulfillment company that specializes in handling the logistics of inventory storage, inventory management, and shipping for other businesses. When you outsource fulfillment to these companies, you can focus more on product sourcing and marketing, and spend less money on warehouse space.

Pros:

- It reduces the need for significant capital investment.

- Logistics companies are more experienced, make fewer mistakes than new companies, and have access to advanced fulfillment technology.

- It’s a scalable process capable of handling inconsistent influxes of orders and company growth.

Cons:

- You have less control over the handling and shipping process, which can impact the customer experience.

- There is potential for service issues if the 3PL ecommerce fulfillment provider’s processes are not aligned with your business’s standards.

- It can be costly, especially if order volumes are low, as 3PLs often charge for storage space and other services.

Best suited for:

- Growing businesses experiencing increasing order volumes and that need to scale quickly.

- Businesses looking to expand into new markets without the need for investing in physical infrastructure.

- Any business that doesn’t have the time, workforce, or money to run its own fulfillment center.

Dropshipping

Dropshipping is a fulfillment model where you don’t keep the products you sell in stock. Instead, when you sell something, you then purchase the item from a third-party — usually a wholesaler or manufacturer — who then ships it directly to the customer.

This model eliminates the need for handling and storing inventory, so it’s much cheaper. But it’s important to choose your suppliers wisely and ensure that you’re selling high-quality items. Low-quality dropshipping has a negative reputation among consumers.

Pros:

- Minimal investment is required to start a dropshipping business.

- There’s no need for physical storage space, which significantly reduces overhead costs.

- It’s straightforward to scale up as there is no inventory to manage directly.

Cons:

- You have less control over shipping times and packaging, which can lead to poor customer service.

- There’s no direct quality control, potentially leading to low-quality products and angry customers.

- There are lower profit margins due to competition and reliance on third-party suppliers, and potential stock issues if suppliers fail to manage inventory properly.

Best suited for:

- New entrepreneurs who want to start an ecommerce business with minimal risk and investment.

- Businesses that want to test new products without committing to large inventory purchases.

Hybrid fulfillment

You don’t have to stick to solely in-house, 3PL, or dropshipping models. You can combine elements of each to create a flexible fulfillment strategy and scale based on your business’ needs.

Businesses might manage some products in-house while outsourcing others to a 3PL company, or mix in dropshipping for particular items. With a hybrid model, you optimize your fulfillment and tailor it to the types of products you sell.

Pros:

- The flexibility to choose the best fulfillment method for different products or markets.

- Businesses can enjoy potential fulfillment cost savings by leveraging the strengths of each method.

- The ability to scale specific segments of the business as needed without overextending resources.

Cons:

- This is a more complex strategy that requires managing multiple fulfillment methods and ecommerce fulfillment company partners.

- It requires careful coordination and integration of automated systems.

- There’s potential for inconsistencies in customer experience if not managed properly.

Best suited for:

- Businesses with a diverse product range or varying customer demands.

- Companies looking to gradually transition between fulfillment models without disruption.

Ecommerce fulfillment challenges: How to optimize ecommerce fulfillment

↑ Voltar Para o TopoEcommerce fulfillment poses a variety of challenges that can significantly impact your efficiency and customer satisfaction. But by optimizing ecommerce fulfillment, you can tackle these challenges head-on and keep everything operating smoothly.

Whether you choose in-house fulfillment, 3PL, dropshipping, or a combination of all of these, check out these common fulfillment challenges and their potential solutions.

Expensive fulfillment costs

Ecommerce fulfillment can get very expensive very fast. The increased operational and overhead expenses can really drag down your business, and that’s true for startups, enterprises, and everything in between.

Here are some elements that contribute to high costs:

- Warehousing. Storing your products with a fulfillment company or distribution center can be very expensive. That applies whether you lease out the space yourself or work with a 3PL provider.

- Packing and shipping. Expenses for packing materials can get costly, especially as many 3PLs charge picking and packing fees. Shipping can also cut into your earnings, especially if you go with the fastest carriers.

- International shipping. If your business expands globally, you may find that shipping costs are higher than expected. Items that cost $10 to ship in the U.S. may turn to $40-$100 to ship to another country.

- Labor. Staffing a warehouse requires hiring people to manage inventory, process orders, pick, pack, and ship products — and it’s not cheap.

- Free shipping expectations. These days, many consumers expect free shipping on their orders. But that means you eat the costs yourself.

Solution: Strategic cost management

As a seller, there are multiple strategic measures you can take to significantly reduce the costs associated with ecommerce fulfillment. While this may be easier for larger businesses with more leverage, there are still options for small businesses.

Here are some ways to more effectively manage fulfillment costs:

- Negotiate with suppliers and shipping carriers. Large businesses have the option of negotiating contracts with suppliers/carriers and getting their items at lower rates. Regularly review these contracts to ensure you’re getting the best deal.

- Use discount shipping platforms. Rather than negotiating yourself, smaller businesses could use a service like WooCommerce Shipping to save up to 67% on postage and streamline label printing.

- Include shipping expenses in product prices. If you choose to offer free shipping, roll some of the cost into the main item’s price.

- Consider a hybrid model. Use a combination of fulfillment strategies. For instance, handle high-volume, predictable items in-house while using dropshipping for slower-moving products to reduce holding costs.

Poorly-organized warehouses

A disorganized warehouse (or home garage) can lead to operational inefficiency, clogging up your supply chain and upsetting your customers. It also directly costs time and money.

Here are some of the potential consequences of a poorly-organized warehouse:

- Misplaced inventory. Items not properly organized are harder to locate, leading to delays in order processing.

- Inefficient use of space. Poor layout can result in unused space or overcrowded areas, which complicates order fulfillment services and slows down the picking and packing.

- Mistakes. A lack of organization can cause more frequent packing errors, leading to customers receiving the wrong items.

- Safety issues. Cluttered and disorganized spaces increase the possibility of accidents and injuries, which can pose a risk to staff.

Solution: Organize and optimize warehouses

If your warehouse is inefficient, an overhaul may be needed to re-sort all your products. And if you’re not in charge of that, it might be time to switch to a better-organized 3PL company.

Here are some ways to improve your warehouse organization:

- Implement a WMS. A warehouse management system uses automation to track where inventory is stored, how it’s moving in the facility, and how much of each item you have. This reduces the number of misplaced items. A good system can also set up efficient picking routes and batch processing that groups similar orders together.

- Optimize the layout. Redesign the warehouse layout to maximize space utilization and workflow efficiency. Ensure that fast-moving items are the most accessible.

- Use clear signage and labeling. Use clearer signs to help workers get around and pick faster. Also adopt systemic bin and rack labeling systems to reduce picking errors.

- Regularly audit and train your team. You should regularly audit warehouse efficiency and see if you have any weaknesses that can be fixed. Continue training staff on how to use the WMS and navigate efficiently.

Backorders and overstocking

Backordering is when customers buy more products than you’re ready to deliver. And if you buy more products than customers are willing to buy, that is overstocking. Both can be a big problem for your business.

Backordering occurs when demand exceeds supply. Current customers may experience delayed shipment times, and potential customers could be driven away by an “out of stock” message.

Overstocking happens when supply exceeds demand, you tie up capital in unsold goods and pay more money storing unwanted products.

These two phenomena are typically caused by poor sales forecasting or supply chain inefficiencies.

Solution: Optimize inventory management

With effective inventory management tools, you can minimize the impact of backorders, prevent overstocking, and maintain even stock levels.

Here are some things to consider for better inventory management:

- Look into enhanced demand forecasting. Utilize advanced analytics and historical sales data to improve accuracy in demand forecasting. Align inventory levels with sales trends to avoid over or understocking.

- Implement real-time inventory tracking. Use an inventory management system that provides real-time inventory updates.

- Consider just-in-time inventory (JIT). JIT is a strategy that involves ordering goods so they’re received “just in time” to make a sale. This minimizes storage costs and prevents overstocking. However, this does make you more vulnerable — if there’s a hiccup in the supply chain, you may be almost immediately out of stock.

- Be sure to hold safety stock. If backorders are a big issue, consider instead keeping an amount of safety stock to handle unexpected surges in demand.

- Use reliable suppliers. Those using dropshipping models, or who otherwise rely on suppliers, should work closely with their providers to prevent severe backordering.

Slow shipping speeds

Slow shipping is a common problem, and unless you’re running a major company with your own carrier service, it’s something you’ll inevitably face. There’s also the issue of items being damaged or lost.

Here are some potential shipping issues you may encounter:

- Carrier inefficiencies. Certain carriers may experience frequent delays due to inefficient setup, leading to extended delivery times or damaged products.

- Poor logistics planning. Inadequate routing, lack of carrier integrations, and suboptimal warehouse locations can all contribute to slow shipping.

- Limited shipping options. Relying on a single carrier can lead to slower shipping when there’s an inevitable service disruption.

- International shipping complications. Cross-border trade often involves longer transit times and can be slowed further by delays at customs.

- Limited shipping locations. You may struggle to expand outside a small area due to lack of warehouses in the region, leading to slow shipping or no service at all.

Solution: Enhance shipping efficiency

If you want to please customers with lightning-fast delivery, you’ll need to pick the right carriers. Those using 3PL providers should ensure that their shipping partners can meet your standards, and dropshipping businesses should carefully select reliable suppliers. Here are some tips for improving efficiency:

- Diversify shipping services and options. Offer multiple shipping options, including expedited services, to cater to different customers and allow a fallback should one carrier be unavailable.

- Source better packaging. To reduce damage, consider using stronger packaging that can stand up to damage, especially for international shipments.

- Implement strategic warehouse placement. Place warehouses carefully or use multiple fulfillment centers closer to your customers to cut down on delivery times.

- Integrate advanced logistics technology. Use logistics software that optimizes routing and carrier selection to streamline shipping.

- Build relationships with reliable carriers. Partner with multiple trusted carriers and negotiate for better service quality and competitive pricing. Also work with customs brokers and use carriers that offer streamlined international shipping to minimize delays.

Inadequate returns management

Returns can be frustrating to deal with, especially if your system isn’t properly equipped to handle reverse logistics. Poorly managing returns can lead to dissatisfied customers and one-star reviews.

Here are some things to keep an eye on related to returns management:

- Complex return processes. Difficult or unclear return procedures can frustrate customers and lead to negative reviews. Learn how to craft an effective return policy.

- Slow refund or replacement times. When you’re slow to issue refunds or deliver a replacement product, it can really damage your reputation.

- High costs of handling returns. If your supply chain is unprepared for reverse logistics, restocking can get very costly.

Solution: Streamline returns

With a proper returns management strategy, you can redirect disappointed consumers and suggest a solution beneficial to everyone. You can avoid most bad reviews and potentially turn a negative situation into a positive one for the customer.

If you want to improve this area of your business, you should:

- Simplify the returns process. Create a clear, straightforward returns policy. No hidden phone numbers, buried support pages, or confusing instructions.

- Offer flexible options. Provide multiple options such as store credit, exchanges, and refunds to cater to different preferences.

- Optimize logistics for returns. Establish dedicated areas in the warehouse for handling inspections, repackaging, and restocking.

- Focus on quality control. Implement stringent quality control to ensure that orders are accurately fulfilled, reducing the rate of returns and complaints.

- Choose reliable third-party suppliers. If using a 3PL or dropshipping model, ensure that their warehouses and systems can accommodate returns. Avoid dropshippers that don’t allow returns, as you’ll eat the cost yourself.

Difficulty growing and scaling

As your ecommerce business grows, you’ll experience increased order volumes, but can your infrastructure handle it? When you outgrow your logistics capacity, it can result in a bottleneck that slows down the ecommerce fulfillment process.

Here are some common growth issues companies encounter:

- Capacity limitations. Existing infrastructure, like warehouse space and staffing, may not be sufficient to handle increased order volumes.

- Supply chain constraints. Scaling often exposes weaknesses in a business’s supply chain, including supplier limitations or logistical bottlenecks.

- Technology gaps. Inadequate technology can hinder a business’s ability to scale efficiently.

- Customer service strain. As order volumes grow, returns grow along with them, maintaining the quality of your customer service can become increasingly difficult.

Solution: Strategically plan ahead

Being proactive is the best thing to do here. Here’s how to prepare for scaling long before it becomes a problem:

- Invest in scalable technology. Implement advanced ecommerce and warehouse management systems that can automate and streamline operations as volume increases.

- Use scalable fulfillment services. Does your 3PL provider have the infrastructure to provide the same stellar quality once your business gets big? Is your dropshipping supplier able to handle massive demand?

- Expand fulfillment options. Consider adopting a hybrid fulfillment strategy that combines in-house operations with 3PL to flexibly manage varying demand levels.

- Strengthen supply chain relationships. Develop strong relationships with multiple suppliers and logistics providers to make your supply chain more resilient.

- Enhance customer support infrastructure. Scale customer service capabilities by employing more staff, using AI software, or outsourcing to handle increased inquiries.

Low-quality tools and integrations

The right integrations can save you time and money. Here are some consequences of choosing the wrong tools:

- Inefficient operations. Tools that don’t effectively integrate with others can lead to fragmented processes and data discrepancies. Order processing and inventory management errors come up often and slow down work.

- A poor customer experience. Inadequate tools can fail to provide the seamless shopping experience that customers expect.

- Limited scalability. Tools that are not built to scale with your business can become a bottleneck to your growth.

Solution: Upgrade your technology

Investing in high-quality tools and integrations is one of the best choices a business can make. Here are some tips for working with the right tools:

- Use integrated systems. Ensure your ecommerce platform, fulfillment and shipping process, and logistics systems are fully integrated with each other for data accuracy.

- Assess and upgrade tools. Regularly review the software your business uses and upgrade to more advanced solutions when available.

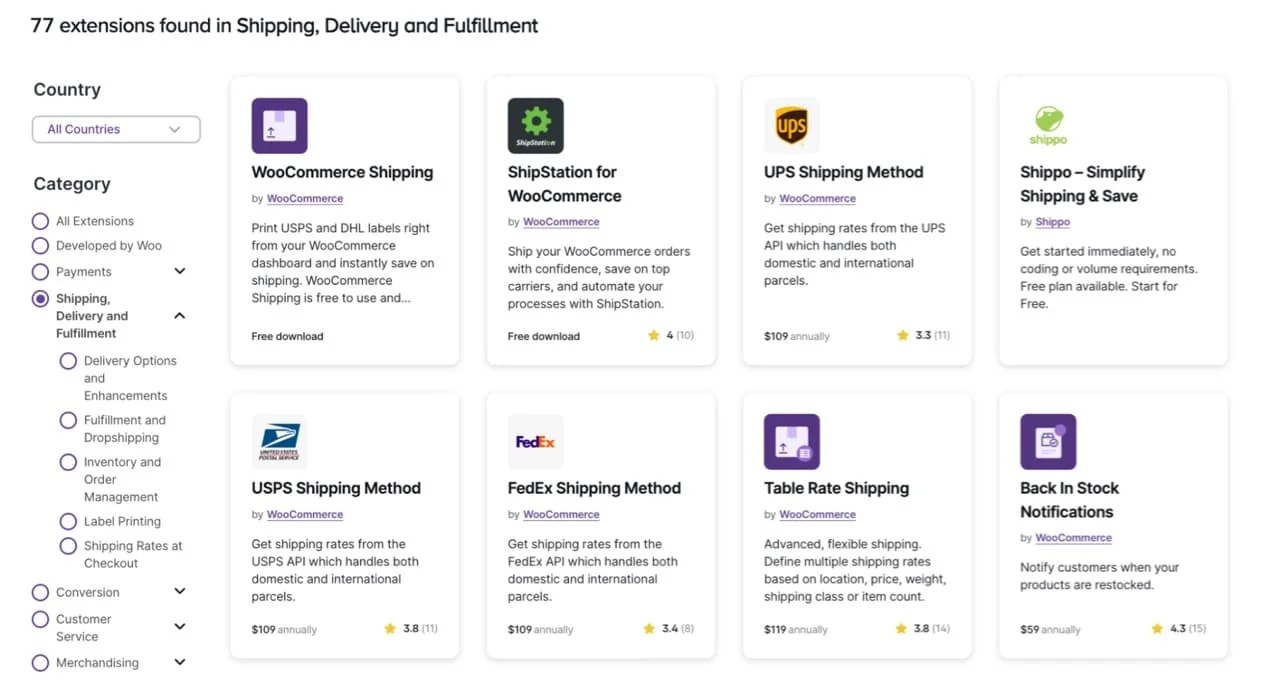

- Use specialized ecommerce platforms. Platforms like WooCommerce offer a wide range of extensions specifically designed to integrate with your existing ecommerce fulfillment services.

- Leverage automation. Utilize tools that use AI to reduce manual tasks and minimize errors. Predictive analytics helps with inventory management, while picking software keeps orders accurate.

Lack of communication

At every step in the supply chain, from suppliers to carriers to customers, communication is key. Many businesses struggle with maintaining clear and consistent communication across all these channels — but it’s often the most important step to fortifying your fulfillment. A lack of communication can result in:

- Internal misalignment. Poor communication between sales, fulfillment, and inventory management teams can lead to delays and inefficiencies.

- Supplier and fulfillment company discrepancies. Insufficient coordination with suppliers and logistics partners can cause inventory shortages, fulfillment delays, and quality issues.

- Customer dissatisfaction. Failing to communicate transparently with customers about their orders erodes their patience and trust.

Solution: Strengthen communication channels

Communication is important every step of the way. Take steps to improve how you speak to consumers, suppliers, and partners, and automate the process as much as possible. Here are some tips for better communication:

- Implement integrated communication tools. Utilize centralized communication platforms that allow all departments and external partners to exchange information in real time.

- Hold regular updates and meetings. Schedule regular meetings with internal teams and key external partners to discuss performance, potential issues, and updates.

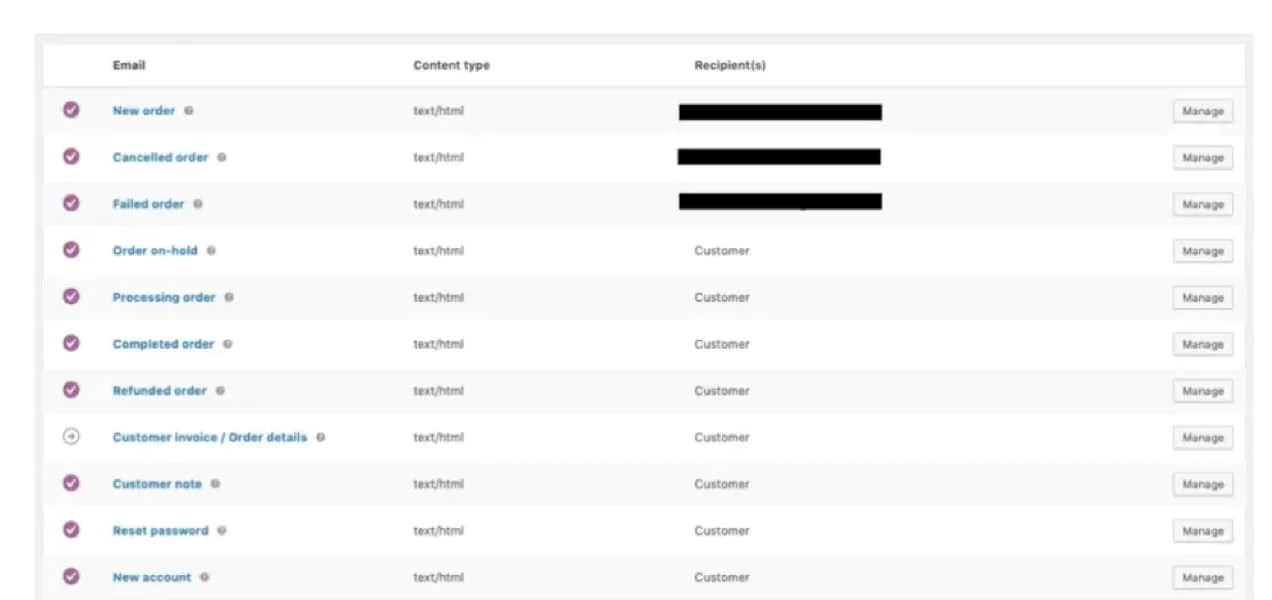

- Send proactive customer notifications. Set up automated systems to provide customers with real-time updates on their order status, including shipment tracking and potential delays.

- Provide accessible support. Provide straightforward access to customer support so potential or current customers can easily get answers.

- Create feedback loops. Establish feedback loops with customers, suppliers, and internal teams. Use their opinions to improve business operations and fix pressing issues.

Ecommerce fulfillment optimization use cases

↑ Voltar Para o TopoFrom established stores seeking to streamline operations to new ventures looking to set a strong foundation from the start, the approach to fulfillment can make a significant difference.

So how might this all play out in an actual business? Let’s look at some things new, existing, and expanding stores may do.

Optimizing fulfillment for existing stores

You already have your business up and running, but you’re encountering issues in the supply chain. Oppressive costs, lack of scalability, and inability to handle a growing customer base are just a few of your daily struggles.

Fulfillment optimization for an existing business will look very different from those just getting started. As your business evolves, so too should your approach to fulfillment.

A great place to start is by switching to WooCommerce, if you’re not using it already. With thousands of extensions to choose from, many of which are specifically designed to improve the fulfillment process, you can implement absolutely any functionality you need to scale.

Next, review all of your processes and determine ways that you can automate them. Automation both saves you a tremendous amount of time — allowing you to focus on other areas of your business — and reduces the chance of human error. For example, you might set up emails that automatically go out to customers after their order ships. Or perhaps you use an extension that syncs inventory levels between all of your tools.

If you haven’t reviewed your return management process recently, make that your next step. An inefficient return policy can eat away profits and complicate the fulfillment process as a whole. Start with writing a great return policy, then put a strategy in place with your team to efficiently handle returns and exchanges.

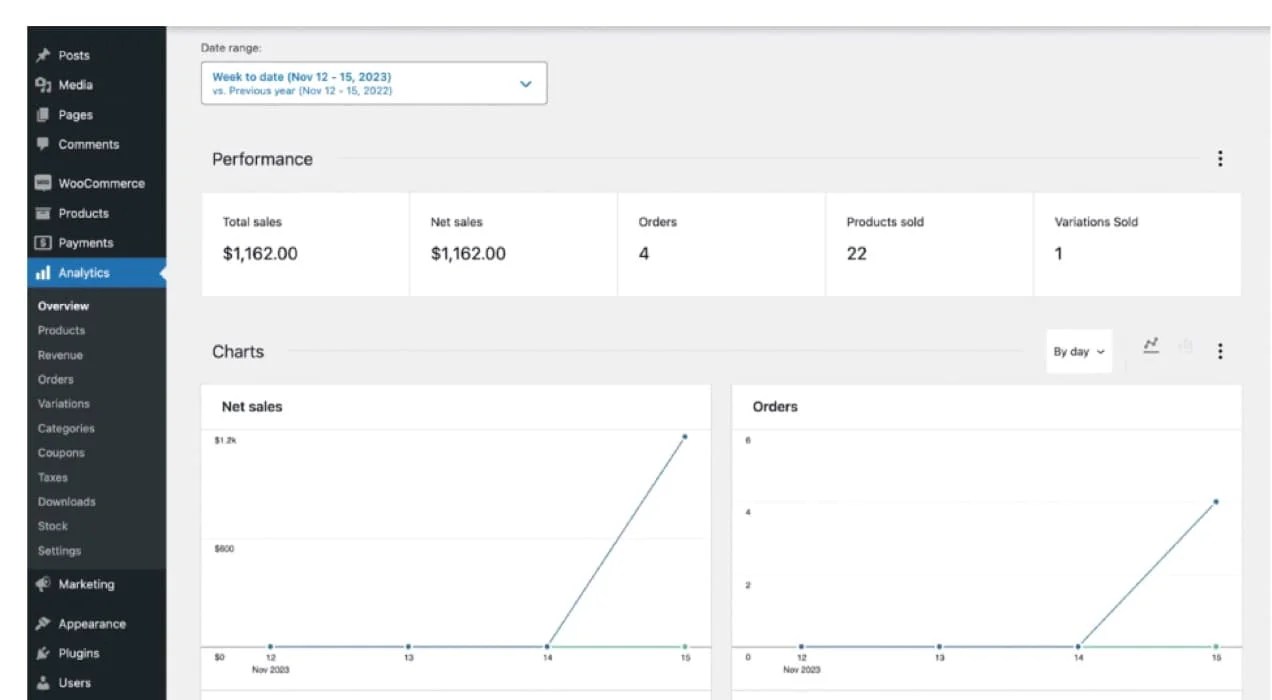

Finally, track your store’s performance metrics and use the information learned to improve your strategies. Keep an eye on order accuracy, fulfillment speed, customer satisfaction, and other KPIs. Then optimize your fulfillment strategy as necessary.

Optimizing fulfillment for new stores

The best way to get started is with WooCommerce. It provides a strong, solid foundation for your store, with everything you need to grow your business to any size. It has a variety of built-in inventory and fulfillment tools, but also offers a wealth of extensions that let you connect to external fulfillment partners and platforms.

Speaking of those external tools, make sure you invest time into choosing the right ones for your fledgling business. Ideally, they’ll support you where you are today, but also allow you to grow without needing to learn a new system. Make sure that your ecommerce platform, inventory management system, shipping partners, and CRM all integrate seamlessly so there’s no information gap.

Finally, spend some time setting up clear communication with customers. Display out of stock notifications — and make sure your stock levels regularly update based on your inventory across any and all storefronts. Create emails that update them on major touchpoints in the fulfillment journey, like when an order is received, shipped, and arrived on their doorstep. You may even want to consider letting them check on their order status in their customer account.

Putting all of these practices into place from the very beginning will set you up for success in the long run.

Expanding to multichannel selling

As your business grows, you may want to expand to other channels like Amazon and eBay. This can be a great way to reach a new audience if you’re properly prepared to handle fulfillment.

If you’re already using WooCommerce, you’re off to a great start. It makes an excellent hub for your multichannel retail strategy, offering a huge variety of integration extensions. With these tools, you can seamlessly sync your ecommerce business with third-party platforms so that inventory and product information is always accurate and up-to-date.

Some of the third-party channels also offer excellent fulfillment services that can make handling orders much simpler. For example, Amazon Multi-Channel Fulfillment can automate the entire order fulfillment process, allowing you to take advantage of their world-renowned delivery capabilities.

And remember: each channel that you use has unique attributes and requirements. Not every fulfillment and shipping solution will be right for every platform. Get to know each one and tailor your shipping options, return policies, and other strategies as appropriate.

Considering dropshipping and and print on demand

Dropshipping and print on demand are two excellent options for ecommerce stores looking to get started quickly and without much initial overhead cost. With dropshipping, you can sell products on your store while allowing a third-party expert to manufacture and fulfill those orders. WIth print on demand, you create unique designs, and your partner prints them on white-labeled products like T-shirts, mugs, and pens. That company then handles fulfillment for you.

Of course, when another company is handling fulfillment and shipping, it’s absolutely critical that you choose the right partner. Your reputation is directly tied to their quality and reliability. Put the research in, read reviews ahead of time, and order product samples to ensure quality. And make sure that you have an excellent understanding of their fulfillment times so that you can keep shoppers abreast.

If there are any issues with an order, make sure you reach out to customers right away and let them know. This might include shipping delays and out of stock items.

The best place to begin is by syncing your dropshipping or print on demand tool with your WooCommerce store. This ensures that inventory levels are accurate and notifies suppliers when you receive an order.

Six great ecommerce fulfillment services

↑ Voltar Para o TopoNow that you know how to set up a successful fulfillment strategy, let’s look at a few of the top ecommerce fulfillment services. When selecting the best ecommerce fulfillment service, consider factors like scalability, integration with your ecommerce platform of choice, cost-effectiveness, reliability, geographic reach, and the quality of customer support.

Here are six excellent options for fulfillment partners that integrate seamlessly with WooCommerce:

- WooCommerce Shipping. WooCommerce Shipping simplifies and streamlines the shipping process for your ecommerce business. Manage all of your orders and print shipping labels directly from the WordPress dashboard.

- Amazon Fulfillment (MCF). Get access to Amazon’s fulfillment network for your multichannel business operations.

- Red Stag Fulfillment. This is a scalable, reliable 3PL and fulfillment partner with 100% order and inventory accuracy guarantees.

- ShipBob. ShipBob offers a comprehensive solution that includes warehousing, inventory management, and ecommerce fulfillment services designed to scale with your business.

- ShipStation. Automate shipping and fulfillment services through this powerful tool that syncs with your WooCommerce store.

- Shipwire. Shipwire is a global fulfillment service that fills ecommerce orders from a variety of channels. It offers powerful real-time tracking and inventory management, along with fast and affordable shipping. This is a great option for a fulfillment partner.

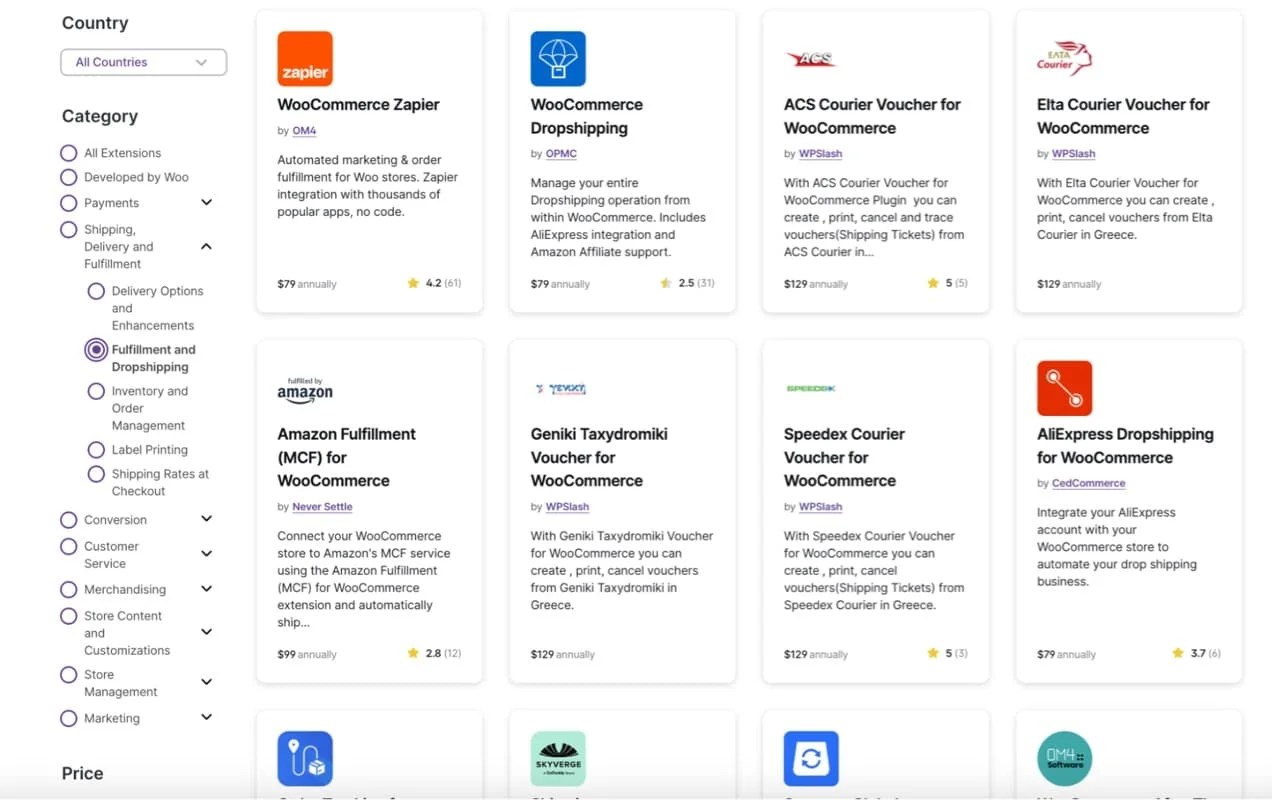

And those are just a few options! See all the fulfillment integrations available in the WooCommerce marketplace.

Ecommerce fulfillment at every level

↑ Voltar Para o TopoFulfillment directly impacts your supply chain, efficiency, stress levels, customer happiness, and the overall success of your business — take the time to put a good process in place.

The best place for any business to start is with WooCommerce. It offers powerful ecommerce tools that streamline inventory management and order fulfillment for every type of business, from a fledgling startup to an enterprise.

With WooCommerce, you’ll maintain full control over your store, benefit from endless flexibility, gain access to a wealth of inventory and fulfillment tools, and get to know a community of business owners who just want to see you succeed. And if retail sales aren’t your focus, WooCommerce also serves as a great B2B ecommerce platform.

Ready to roll? Get started with WooCommerce.

About